Blog

Get the scoop on our latest flavor releases, sweet recipes, company news, and more!

-

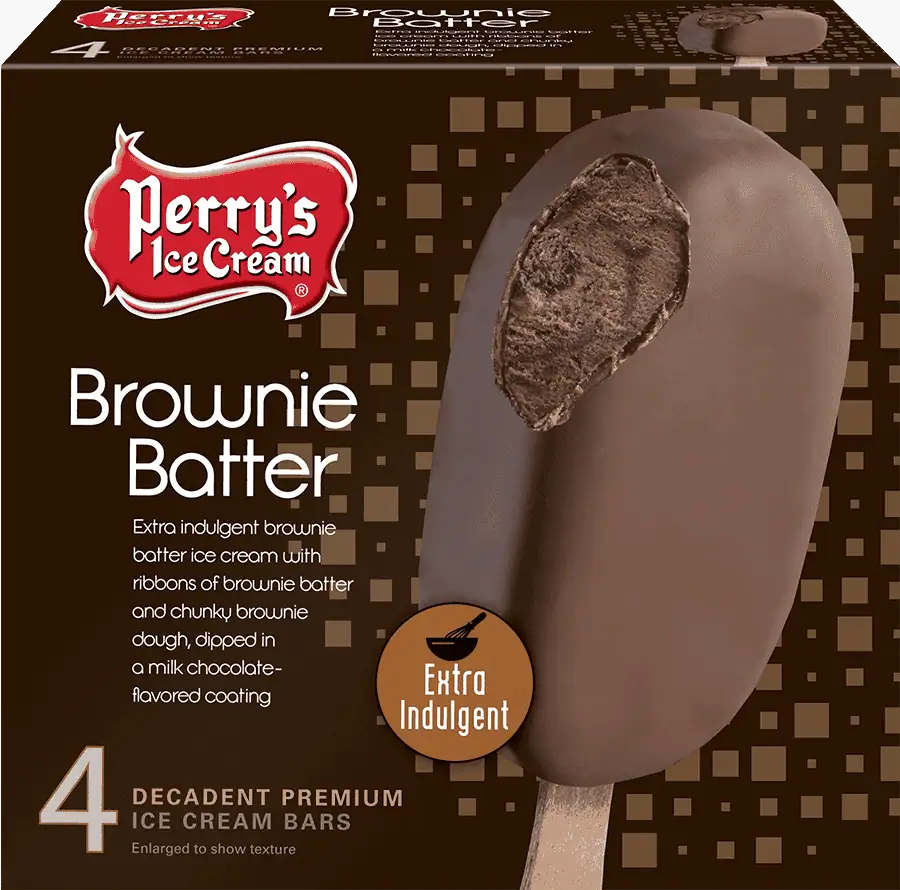

Perry’s Ice Cream’s NEW Extra Indulgent Novelties raise the bar (on stick ice cream)

Premium offerings are the leading motivator for consumers to buy more frozen treats from a retail store.* Akron, N.Y. – March 18,…

-

Southern Tier Brewing Company Brings a Sweet Treat Sure to Delight, Orange Twist

Lakewood, N.Y. – March 11, 2024 – Southern Tier Brewing Company is once again proud to launch a seasonal release in collaboration…

-

Our 2024 New Flavors Have Arrived!

You’ve been waiting patiently, and we’re happy to announce that Perry’s Ice Cream’s new flavors are here! There’s no shortage of good…

-

Give a Pint of Blood through ConnectLife, Get a Pint of Perry’s Ice Cream

We’ve proudly teamed up with ConnectLife, WNY’s only community blood center and federally designated organ, eye, and tissue procurement agency for the…

-

Find your perfect ice cream and classic romance movie pairing

If cozying up with a pint of creamy, rich, extra indulgent ice cream and a classic romance movie is your ideal Valentine’s…

-

Top Selling Perry’s Ice Cream Flavors of 2023

2024 is officially here! If your resolution is to try more ice cream flavors this year, you’re in good company. Check out…

-

The Perfect Ice Cream and Pie Pairings

On the hunt for holiday dessert ideas? You’ve come to the right place. After all, we think about dessert like it’s our…

-

Get your freezer ready for game day with Perry’s sports ice cream flavors

We all scream for ice cream (and our favorite team!). We can’t think of a better way to enjoy game day than…

-

Easy Vampire Halloween Milkshake Recipe

Halloween is full of tricks and treats, but we are partial to the “treats” ourselves. Ready to sink your fangs into this…

-

Ice Cream for Kosher-conscious Consumers

Are you looking for “kosher ice cream near me”? You’ve come to the right place! Perry’s Ice Cream proudly offers more than…