Sustainability – Perry's Ice Cream

Sustainability

Our commitment to the “Good Stuff” goes beyond the cone. It’s about sustaining our communities and nurturing the environment, ensuring each scoop reflects doing good in every way.

About Sustainability at Perry’s Ice Cream

An integrated sustainability culture requires consideration of People, Planet and Performance. Our annual Good Stuff Report breaks down our sustainability initiatives into 4 categories: Culture & Partnerships, Environment, Growth, and Process & System Improvements.

Check out some of the highlights from our 2023 Good Stuff Report below, or download the full report.

Sustainability Initiative #1: Culture & Partnerships

Long Term Goal: To be known as an employer of choice and responsible corporate citizen

$1.4 million in corporate donations since 2010

Over 7,600 donations in 3 years

16 leaders certified in mental health first aid

Sustainability Initiative #2: Environment

Long Term Goal: To be recognized as a “zero landfill” operation and maximize the value of our resources

through improved efficiencies, productivity and utilization of technology

Powering our facility with

160 tons less CO2 released in 2023

Sustainability Initiative #3: Growth

Long Term Goal: To manage growth and maintain profitability for reinvestment

A record breaking 11.7 million gallons of ice cream manufactured in 2023

23rd largest ice cream brand in the US and #1 brand in the Buffalo Mid-Atlantic region*

*2023 Nielsen, Total US Market, YE 2023; Nielsen, Buffalo Mid-Atlantic Market, YE 2023

Perry’s products available at 3 NEW Ohio chains

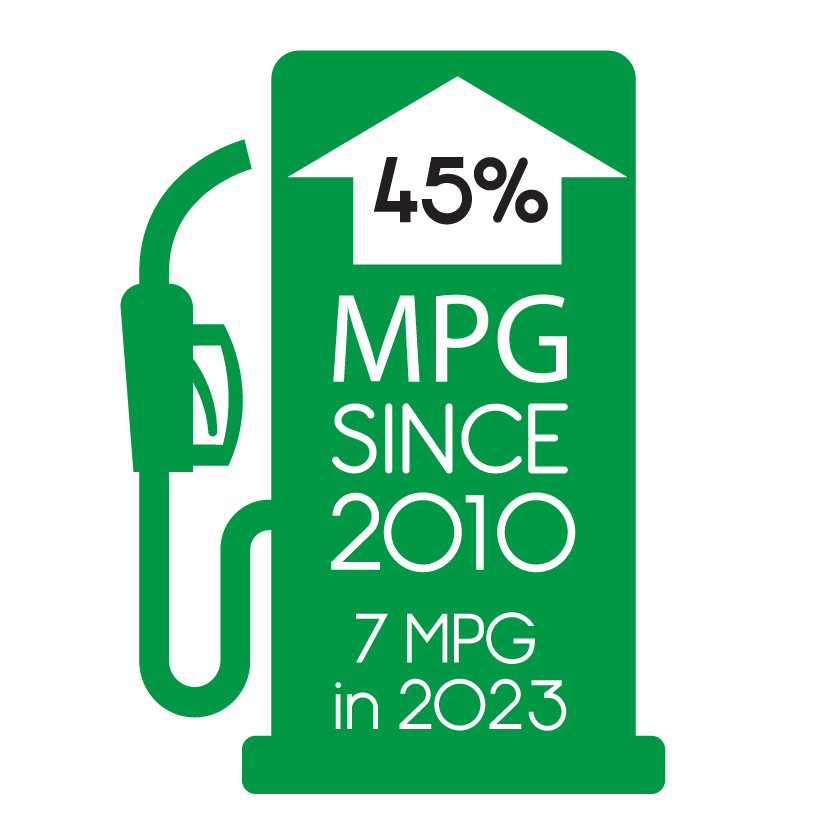

Sustainability Initiative #4: Process & System Improvements

Long Term Goal: To continuously improve our processes to eliminate waste and increase operational effectiveness

Added NEW super premium ice cream bar capability, where indulgence meets innovation

Implemented paperless training documents, quizzes and forms

5,000 sheets of paper saved annually by converting to electronic trip sheets & mileage forms